Casters & Wheels

Wholesale Casters & Wheels Just In One Placce

Techin stands as your reliable source for a vast selection of casters. Our product line accommodates various industries and applications, promising efficient and superior quality caster solutions. With a deep understanding of the caster industry, Techin stands ready to fulfill all your specific needs with customized solutions, available in a variety of specifications. Choose Techin for a seamless, quality-driven experience, where your requirements are met with precision and expertise.

Wanna dig deeper in more products?

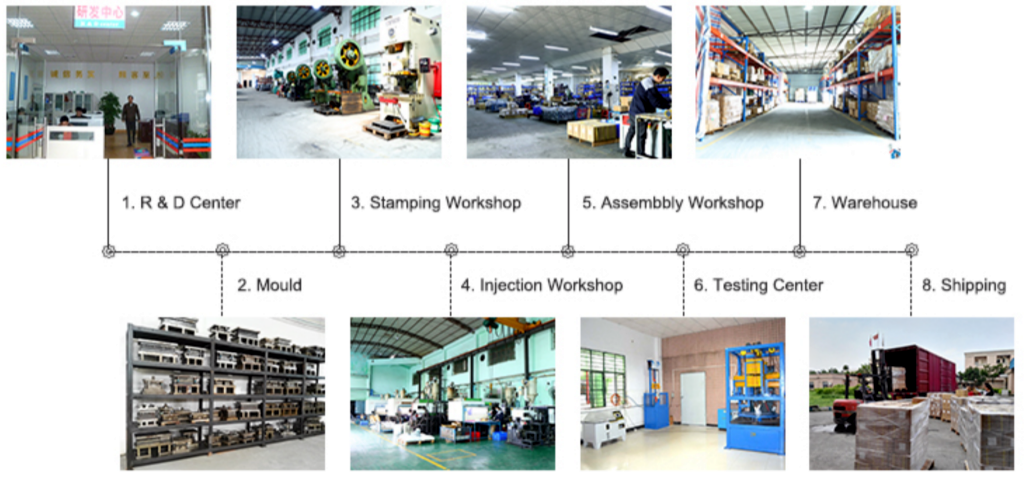

Caster & Wheel End-to-End Production Process

Caster and wheel, often overlooked, are integral to various aspects of daily life. From shopping carts to industrial equipment, these simple yet efficient components serve as the unsung heroes of mobility. The production process behind caster wheels is a blend of cutting-edge technology and expert craftsmanship.

Research and Development: It all begins with innovation at the Research and Development Center. Engineers and designers continuously explore new materials and methods to enhance caster wheel performance.

Mold Creation: Precision is the focus in mold creation. Skilled artisans employ advanced technology to craft molds that define the dimensions of caster wheels.

Stamping and Injection Workshops: In these workshops, high-tech machines transform raw materials into caster components. Stamping creates durable metal pieces, while injection molding produces resilient plastic parts.

Assembly Workshop: Skilled workers meticulously assemble the caster wheels, ensuring they roll smoothly and securely.

Testing Center: Quality is paramount, with each caster wheel undergoing rigorous testing to meet and exceed industry standards.

Warehouse: Approved caster wheels are temporarily stored in an organized warehouse, awaiting distribution.

Shipping: Finally, these wheels are shipped worldwide, providing effortless mobility for various applications.

In this process, innovation and precision combine to make caster wheels an essential part of our daily lives.

A Comprehensive Guide to Casters

Caster and wheel, often overlooked, are integral to various aspects of daily life. From shopping carts to industrial equipment, these simple yet efficient components serve as the unsung heroes of mobility. The production process behind caster wheels is a blend of cutting-edge technology and expert craftsmanship.

Research and Development: It all begins with innovation at the Research and Development Center. Engineers and designers continuously explore new materials and methods to enhance caster wheel performance.

Mold Creation: Precision is the focus in mold creation. Skilled artisans employ advanced technology to craft molds that define the dimensions of caster wheels.

Stamping and Injection Workshops: In these workshops, high-tech machines transform raw materials into caster components. Stamping creates durable metal pieces, while injection molding produces resilient plastic parts.

Assembly Workshop: Skilled workers meticulously assemble the caster wheels, ensuring they roll smoothly and securely.

Testing Center: Quality is paramount, with each caster wheel undergoing rigorous testing to meet and exceed industry standards.

Warehouse: Approved caster wheels are temporarily stored in an organized warehouse, awaiting distribution.

Shipping: Finally, these wheels are shipped worldwide, providing effortless mobility for various applications.

In this process, innovation and precision combine to make caster wheels an essential part of our daily lives.

Navigating the World of Caster Materials

In the dynamic world of caster production, the choice of material is pivotal in determining the functionality and durability of the product. Here, we delve into the various materials commonly used in the manufacturing of casters, each offering unique characteristics and benefits:

- Polyurethane: A versatile material, PU finds applications ranging from children's toys to airplane parts. When used in casters, it offers excellent damping properties and retains a high load capacity, absorbing shocks in vibrating environments effectively.

- Nylon: Known for its excellent abrasion resistance, nylon casters facilitate smooth surface-to-surface contact. The silky property of nylon makes these casters sturdy and floor-friendly, minimizing friction and ensuring longevity.

- Rubber: A common choice for both industrial and domestic applications, rubber casters can withstand deformation easily. The elasticity of rubber grants it flexibility and stretchability, making it a reliable choice for various applications.

- Aluminium: Offering a high strength-to-weight ratio, aluminium casters are ideal for durable and lightweight applications. These casters promise increased mobility due to the material's lightweight nature, guaranteeing durability without compromising on strength.

- Cast Iron: When it comes to handling brute forces, cast iron casters stand unrivalled. Capable of supporting heavy industrial equipment, these casters are known as the beasts in industrial settings, with the ability to withstand high levels of pressure and roll with relative ease.

- Stainless Steel: A popular choice in recent times, stainless steel casters offer durability and strength, making them a worthy consideration for various applications.

European Standards: A Guide to Compliance

In the caster industry, several European standards serve as guidelines to ensure the quality, safety, and environmental compatibility of products. Here, we provide an overview of some pivotal standards that are commonly adhered to:

- EN 840: This standard applies to mobile waste containers with capacities up to 1700 l that are used by the general public. It specifies the essential dimensions to ensure the interoperability of the containers with lifting devices.

- PAHs (Polycyclic Aromatic Hydrocarbons): This regulation governs the restriction of PAHs in consumer products, including casters and wheels. Techin ensures that its products comply with the limits set for PAHs, safeguarding both the environment and public health.

- REACH (Registration, Evaluation, Authorization and Restriction of Chemicals): A European Union regulation that addresses the production and use of chemical substances, and their potential impacts on both human health and the environment. Techin is fully compliant with REACH, ensuring that our products are safe and environmentally friendly.

- RoHS (Restriction of Hazardous Substances): This directive restricts the use of specific hazardous materials found in electrical and electronic products. Techin adheres to RoHS standards, ensuring that our products are free from harmful substances.

- EN 12530: This standard outlines the requirements and dimensions for equipment casters and manually operated wheels and casters used in public facilities such as hotels, restaurants, schools, or hospitals.

These standards are integral in guiding manufacturers to produce products that are not only of high quality but also safe and environmentally responsible. Adherence to these standards is often seen as a mark of reliability and trustworthiness in the industry.

Understanding the Lifecycle of Casters

In the realm of caster usage, understanding the lifecycle of casters is pivotal in planning proactive maintenance or replacements, thereby mitigating potential risks associated with caster failures. Here, we delve into the various factors that influence the durability and lifespan of casters:

- Material Considerations: The materials used in the construction of casters significantly influence their lifespan. For instance, casters that frequently come into contact with water, corrosive liquids, or air tend to have a shorter lifespan. Moreover, the choice of material can also affect the caster's appearance over time. Utilizing stainless steel rigs, for example, can offer more years of service and maintain a better presentation of your product, preventing rust and corrosion that can reflect poorly on the facility's operation.

- Maintenance Practices: Proper maintenance practices can extend the lifecycle of casters. Regular check-ups and timely replacements can prevent issues such as inventory damage, product flow interruptions, and potential workplace injuries. It is recommended to change casters at certain intervals to avoid downtime caused by machinery or cart failures.

- Appropriate Caster Selection: Choosing the right caster for the specific job at hand is crucial. Different applications demand different types of casters, and selecting the appropriate one can prevent premature wear and tear, thereby extending the caster's lifespan.

- Environmental Factors: The environment in which the caster operates can also affect its durability. Factors such as exposure to water and corrosive liquids can shorten the caster's lifespan. Hence, understanding the specific environmental conditions and selecting casters accordingly can be beneficial in prolonging their service life.

For further information or assistance in selecting and maintaining casters, our professional sale’s advice is available to guide you in making informed decisions.

Guiding Principles for Selecting Casters

Selecting the right caster and installing it correctly is a vital aspect in ensuring the longevity and functionality of your equipment. Here, we outline a systematic approach to guide you through the process of selecting and installing casters:

- Determine Your Product and Mounting Type: The first step involves identifying the type of product you are working with and the appropriate mounting method. Different products may require varied mounting techniques, and understanding this is crucial in selecting the right caster.

- Understanding Load Capacity: Before selecting a caster, it is essential to determine the load capacity it needs to handle. The load capacity is calculated using a specific formula that considers various factors including the deadweight of the transport unit, the maximum additional load, and the number of wheels or casters used. Safety factors, influenced by the speed and the ratio between wheel diameter and height of the obstacles, also play a significant role in determining the load capacity.

- Select Your Tread Material: The tread material significantly influences the operational comfort, smooth-rolling performance, and resistance characteristics of the wheels or casters. It is vital to choose a tread material that is softer than the floor to prevent damage.

- Determine Maneuverability: Understanding the maneuverability factors such as starting, rolling, and swivel resistance is crucial in selecting the right caster. These factors are influenced by various elements including wheel diameter, load, floor condition, and bearing type.

- Select the Bearing Type: The bearing type is a critical aspect that affects the rolling characteristics of a wheel. Different bearing types, such as plain bore bearing, roller bearing, and central ball bearing, offer varied performance characteristics and are suitable for different applications.

- Consider Your Application’s Environmental Influence: The environmental conditions where the caster will be used should be considered, especially in cases where the components may come into contact with aggressive substances. Factors such as chemical resistance, temperature, and humidity can influence the choice of caster.

- Additional Options and Requirements: Depending on your specific needs, you might require additional features such as locking systems for rolling and/or swivel motions, or brake systems. Understanding these additional requirements is vital in selecting the right caster.

Common Pitfalls When Buying Castors and Wheels

Ordering casters and wheels for your business might seem straightforward, but there are several common pitfalls that can complicate the process, especially for hardware supermarket buyers and caster distributors in Europe. Being aware of these issues can save you time, money, and resources while ensuring that you receive products that meet your specific needs.

- Ignoring Quality Standards

- Narrow Product Selection

- Lack of Custom Options

- Poor Communication

- Unclear Payment Structure

Getting the right casters and wheels for your business is more than just clicking ‘Get A Quote’. It’s about making smart choices, and that’s where Techin comes into play. We offer you a wide range of top-notch products, flexible custom options, and straightforward payment plans, all while keeping the lines of communication open.

By choosing Techin, you’re opting for a supplier that gets the ins and outs of the B2B world. We’re here to make your buying process hassle-free and help you steer clear of common mistakes, setting you up for success in your business.

A Brief Self-Nomination, Why Choose Techin?

When you choose Techin, you're choosing a legacy of quality, a breadth of product variety, and the advantage of custom solutions. As a B2B-focused company, we understand the unique needs of different types of customers, like hardware supermarket buyers and caster distributors in Europe.

Finding the right supplier for your business is crucial. Techin stands out as the preferred partner for high-quality casters and wheels, designed to meet your specific business needs.

- Quality: In-house factory ensures products meet European standards.

- All in one: A comprehensive range of casters and wheels for multiple applications.

- Customization: Tailored solutions to fit your unique requirements.

- B2B Expertise: Wholesale-only model, perfect for hardware supermarket buyers and caster distributors.

With Techin, you’re not just buying a product; you’re securing a partnership that understands your business needs. From quality to customization, we’ve got you covered.

Frequently Asked Questions

To continue to provide valuable information for our B2B clients, here are another ten FAQs that delve deeper into the aspects that most concern our target customers.

Do you offer free samples?

Yes, we offer product samples to give you a firsthand experience of the quality and variety we bring to the table.

Do you have any certifications?

Certainly, our products proudly bear recognizable certifications like EN840, REACH, RoHS, PAHs, EN12530 etc. These symbols of excellence guarantee that you receive products that meet international standards.

Is there a warranty period for your products?

All of our products come with a standard warranty period, reinforcing our commitment to quality and customer satisfaction.

How do you ensure timely delivery of orders?

We have a streamlined production schedule and robust logistics partnerships to ensure that your orders are delivered on time, every time.

Is it OK to print my logo on casters ?

Sure. We could build the molds and fixtures upon your sample or technical drawings, add your logo on fork or wheel, and pack the casters in your branded carton